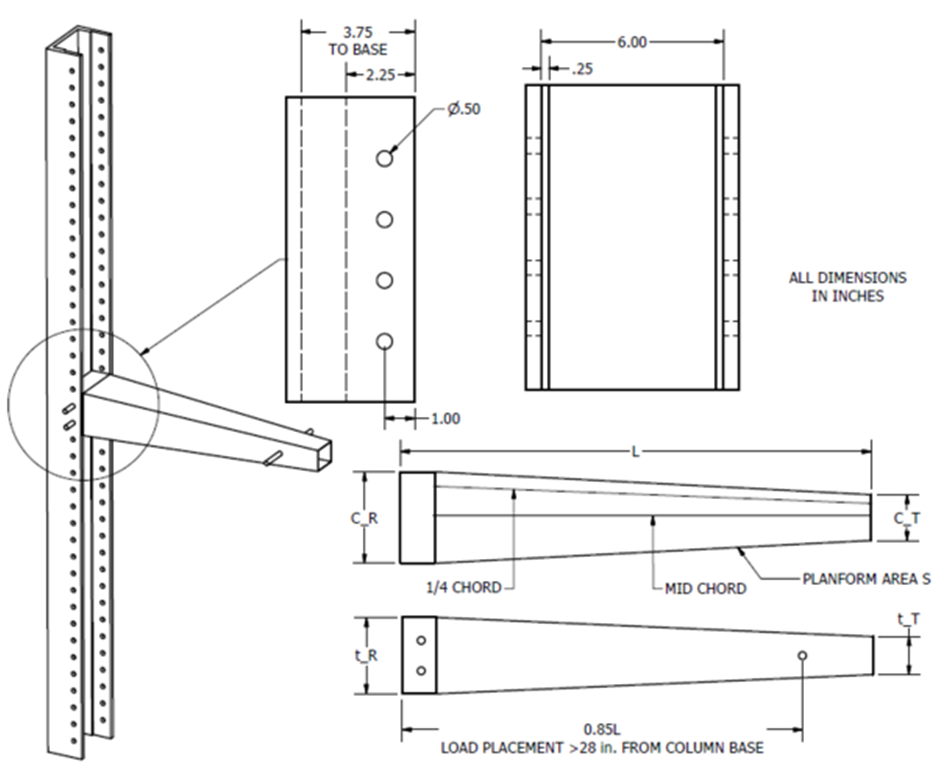

For a design class at Princeton, I was on a team tasked with

designing and constructing an aluminum monocoque structure

that was meant to be a model of an airplane wingbox.

The objective of this lightweight "boxlift crane" was to be under

3 lbs, and support 500 lbs located at 85 percent of its total

length, measured away from the column to which it was

attached. This load was applied at two different lateral

locations: at the mid chord line (a tension test), and at the

quarter chord line (a torsion test).

Additionally, the load placement was required to be at least 28

inches away from the base of the column. The crane itself had

to have a root chord length (C_R) of 6 inches, a root thickness

(t_R) of less than 5 inches, and a tip thickness (t_T) of less

than 3 inches. Furthermore, the crane had to be tapered in

planform, with a taper ratio (C_T/C_R) between 0.5 and 0.75,

and an aspect ratio L^2/S, where L is length and S is area,

of greater than 6.5.

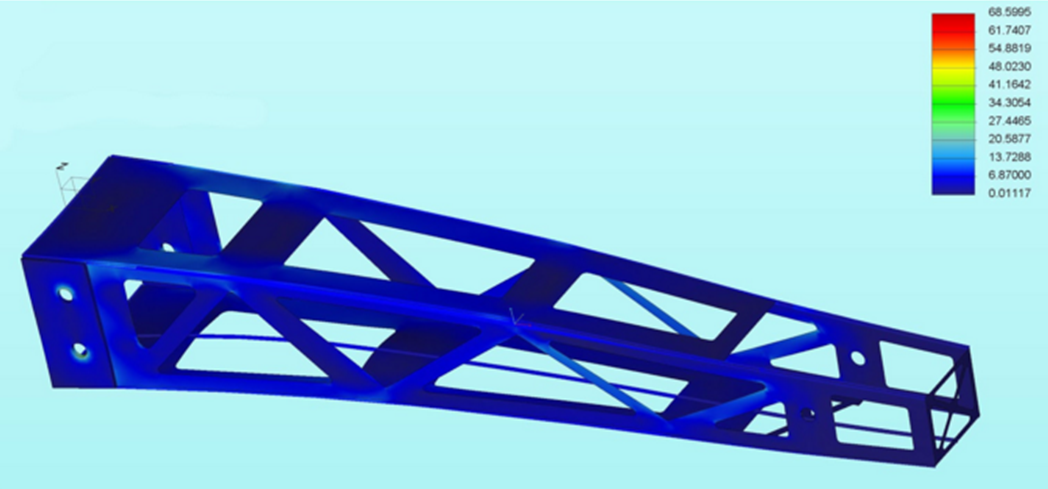

Our design met and exceeded specifications by weighing 2 lbs,

16 ounces, and only undergoing plastic deformation at a loading

in excess of 715 lbs!